There are only a handful of engine makers that power regular commercial aircraft today. The main three are Pratt & Whitney, Rolls-Royce, and General Electric. They have their own efficiency and decarbonization strategies, such as Rolls-Royce's hydrogen jet engine test in collaboration with easyJet last week.

However, with the advent of novel propulsion technologies, there is also a new type of engine maker carving out space for itself in the sustainable future of flight. Several startups have already gotten quite far in testing hydrogen fuel-cell technology, with, for instance, ZeroAvia gearing up for the first flight of its Dornier 228 testbed aircraft.

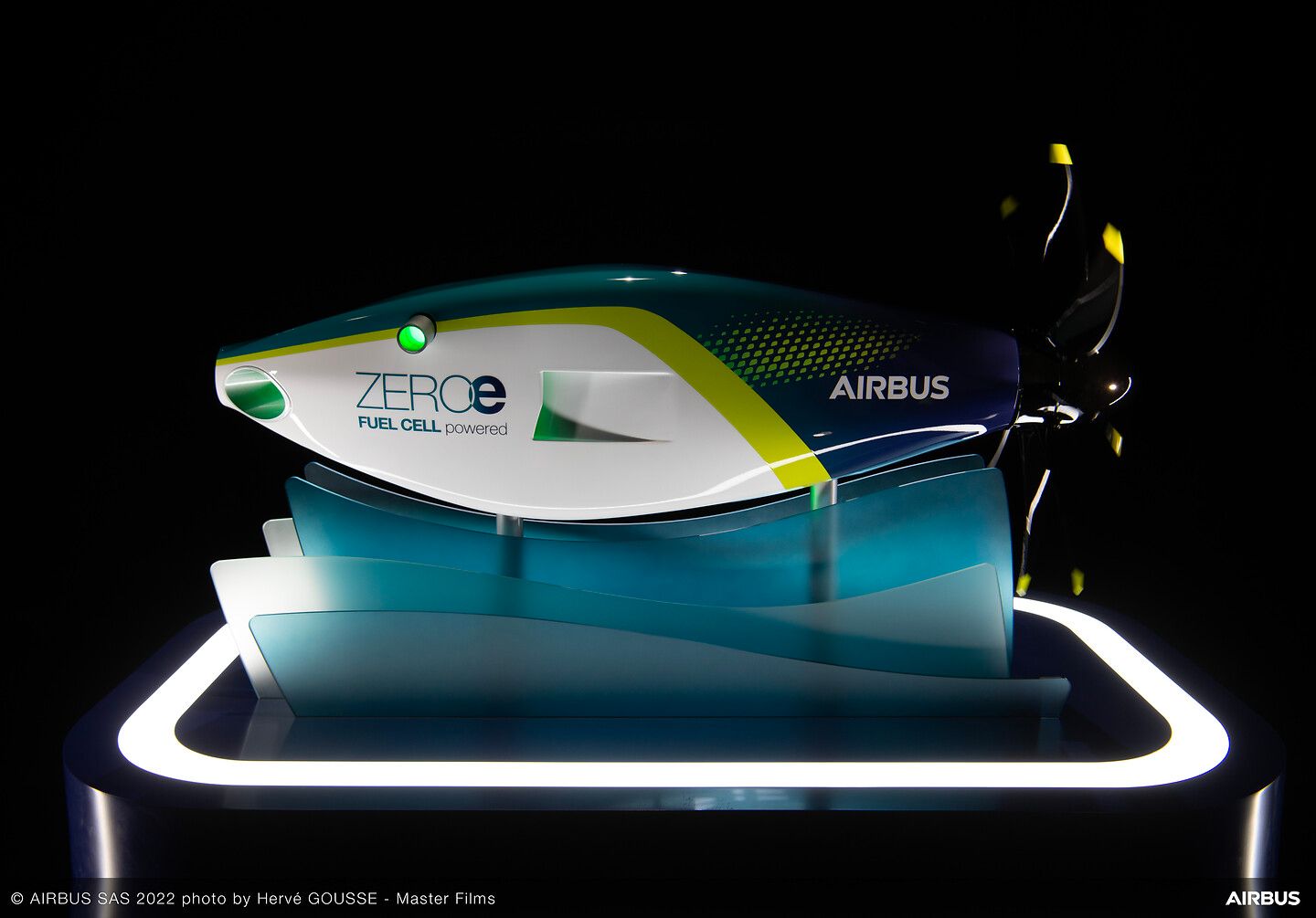

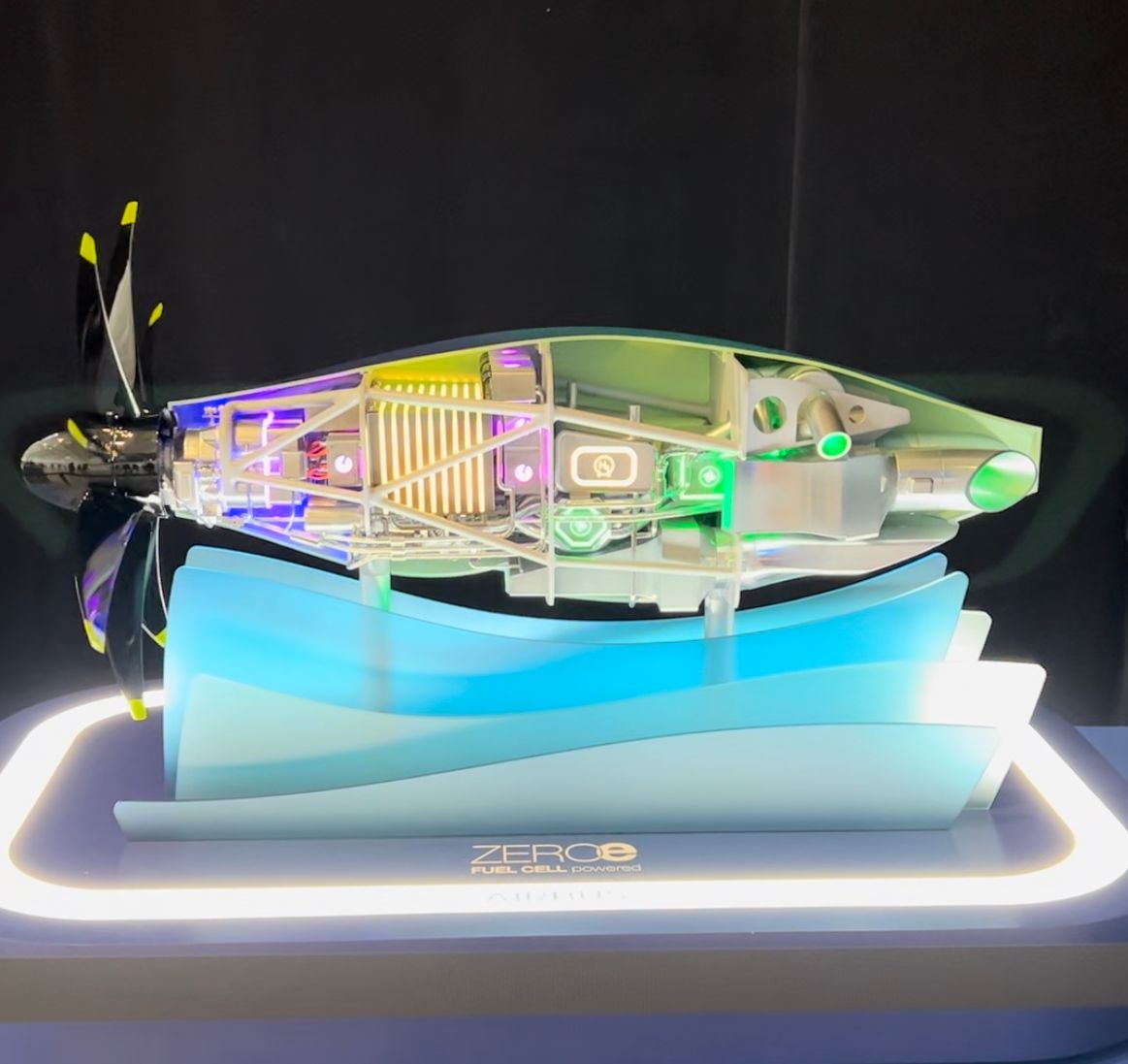

Airbus has partnered with CFM International (a joint project between GE Aviation and Safran) to test direct hydrogen combustion technology. Meanwhile, last week, the European aerospace manufacturer revealed its own hydrogen fuel-cell technology engine.

For now, it is a matter of developing the technologies to make hydrogen-electric propulsion a reality. However, when that is done, Airbus may decide to bring in a partner - or it could decide to produce its own hydrogen-fueled powerplant.

While presenting the new fuel-cell project at the Airbus Summit in Toulouse, the company's VP for Zero Emission Aircraft, Glenn Llewellyn, said,

"Right now, what we are doing is developing the technologies. We're developing the methods for integrating those technologies into a fuel cell-type engine. It doesn't mean that Airbus will do this on its own in a subsequent step before we decide to commercialize that technology. We might decide that that's the best approach. But we could easily also decide to partner."

Direct combustion vs. fuel-cell

Airbus is, of course, already partnering across its hydrogen propulsion technology ecosystem. As we previously mentioned, CFM will ground and flight test hydrogen direct combustion technology on Airbus' A380 ZEROe demonstrator aircraft. The engine maker will modify the combustor, fuel system, and control system of a GE Passport turbofan to run on hydrogen.

While direct combustion technology would burn the hydrogen the same way other combustion engines burn Jet A, fuel-cell engines generate electricity through an electrochemical reaction. They differ from batteries in that they require a continuous source of fuel and oxygen. With a hydrogen fuel cell, there is no CO2 or NOx. While water vapors are of concern, Airbus has a program in place testing the potential contrail formation from burning hydrogen at altitude.

Fuel-cell technology has been available to the automotive industry for some time. However, what is sufficient for ground transport does not meet either the safety or the efficiency requirements of aviation. In order to generate enough power, the fuel cells need to be "stacked" together, which may incur a weight penalty for the overall system.

Parallel paths

Airbus will be working on both direct combustion and fuel-cell technology as parallel pathways, deciding on which will be the more likely to power the ZEROe aircraft it does bring to market, if the timeline still stands, by 2035.

Llewellyn said,

"They are today two parallel paths. And we're exploring the potential of those different technologies, but from a climate perspective, and from a scalability technology perspective, and we are making the decisions later about what finally the technology would be that we take to a commercial aircraft, but we're not at that point yet."

Want to know more about sustainability in aviation?